Rubber products are ubiquitous in modern life, ranging from tyres and hoses to seals, belts, and gaskets. To ensure these products perform reliably and last a long time, the proper additives are crucial. One often-overlooked, but essential, ingredient is rubber wax. As the demand for high-performance rubber products continues to grow, the strategic use of rubber processing wax, anti-ozone wax for rubber, and rubber wax additives has become indispensable for manufacturers seeking durability, efficiency, and cost-effective solutions.

In this article, we examine the primary types of rubber waxes, their diverse applications and industrial functions, and how synthetic waxes surpass traditional alternatives in rubber compounding.

Rubber wax, in essence, is a complex mixture of high-molecular-weight hydrocarbons, typically derived from petroleum refining processes. Its primary function is to protect the rubber from degradation caused by factors like ozone, UV radiation, and weathering. By migrating to the surface of the rubber, it forms a protective layer that acts as a barrier against these harmful elements.

There are several types of rubber wax, each with slightly different properties and applications. Understanding these differences is key to selecting the right wax for your specific needs.

Rubber processing wax is engineered to improve the flow and dispersion of rubber compounds. Added during the mixing and processing of the rubber compound, it acts as a lubricant and dispersing agent. It aids in the homogenization of the compound, improves flow during molding, and reduces tackiness, ultimately streamlining the manufacturing process.

Synthetic waxes offer consistent melting points and tailored molecular weights, making them ideal for precision-driven rubber processing environments.

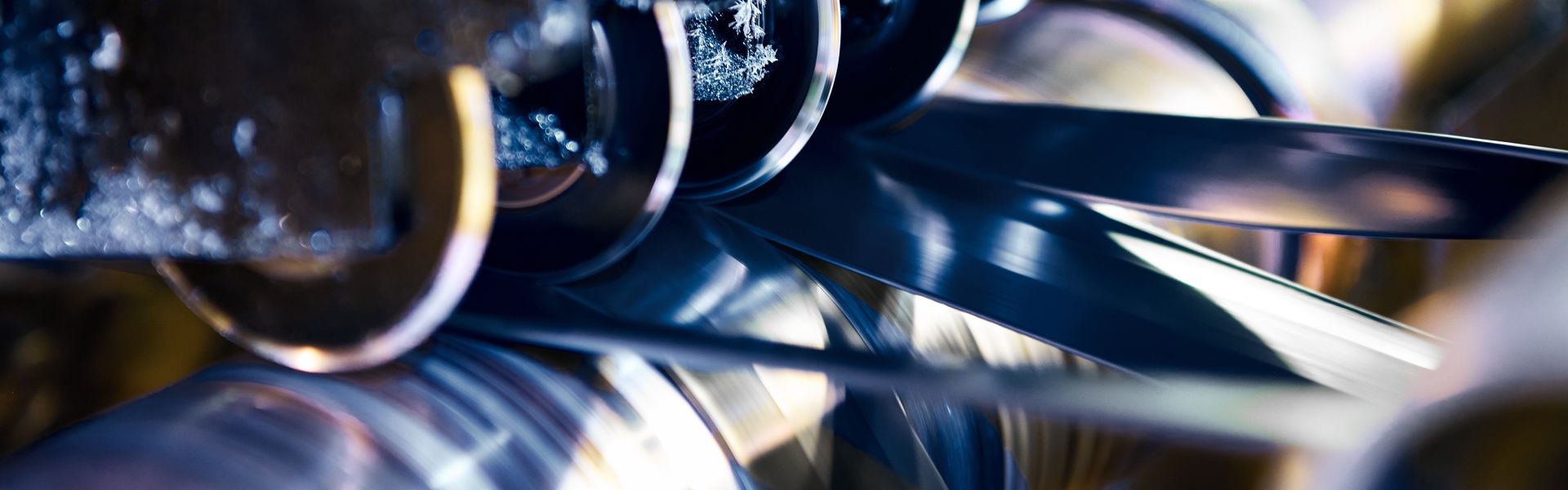

Ozone degradation is a significant threat to rubber products exposed to outdoor or high-stress environments. Anti-ozone wax for rubber is specifically designed to combat this issue. It forms a protective surface layer that migrates to the rubber surface over time, shielding it from ozone attack and cracking.

These waxes are especially critical in automotive tyres, conveyor belts, and industrial seals where ozone exposure is frequent and performance failure is costly.

This is a broader category encompassing waxes used to impart specific properties to the rubber compound. Rubber wax additives are used to fine-tune compound characteristics such as flexibility, hardness, surface appearance and ageing resistance. They can be blended with other additives to achieve targeted performance metrics.

Synthetic waxes offer tighter control over additive behaviour, ensuring predictable performance across production batches.

Protective wax for rubber products provides a general protective barrier against environmental degradation, extending the lifespan of the finished rubber product. It helps prevent discolouration, hardening, and cracking due to exposure to sunlight, rain, and other elements.

It is applied post-processing to safeguard finished goods during storage, transport, and use.

Synthetic protective waxes are engineered for durability and consistency, making them ideal for high-value rubber components in demanding sectors.

Rubber compounding wax is a critical ingredient in the formulation stage, influencing the final product’s mechanical and chemical properties. It interacts with other compound elements to optimize performance. These waxes contribute to a range of properties, from processability to long-term durability, ensuring the final product meets the desired specifications.

Strategic Roles:

Synthetic waxes provide unmatched formulation flexibility, allowing compounders to meet exacting specifications without compromising production efficiency.

Incorporating the right rubber wax into your rubber compound offers a multitude of benefits:

Selecting the appropriate rubber wax depends on several factors, including the type of rubber used, the intended application of the product, and the environmental conditions to which it will be exposed. Factors to consider include:

Rubber wax is a vital component in the production of high-quality, durable rubber products. From facilitating processing to providing long-term protection against environmental degradation, the right wax can significantly enhance the performance and longevity of your rubber compounds. While natural waxes have historically played a role, synthetic waxes offer superior consistency, tailored functionality, and scalable performance advantages that align with modern industrial demands.

Choosing the right rubber wax is an investment in the quality and reliability of your rubber products, contributing to long-term performance and customer satisfaction. From rubber processing wax that streamlines manufacturing, to anti-ozone wax for rubber that defends against environmental degradation, and rubber wax additives that fine-tune compound behaviour, synthetic solutions deliver measurable value. Add to that the benefits of protective wax for rubber products and rubber compounding wax, and it’s clear that synthetic waxes are the strategic choice for manufacturers focused on durability, efficiency, and cost control.

In a competitive market where performance matters more than idealism, synthetic rubber waxes emerge as the pragmatic solution for achieving industrial success.

Plant: Strada Quaglia, 26 - 10026, Santena (TO)

Offices: NEXTTO Polo Uffici Lingotto

Plant: Strada Quaglia, 26 - 10026, Santena (TO)

Offices: NEXTTO Polo Uffici LingottoLegal address: Via IV Novembre 30 - 12025, Dronero (CN)

VAT: IT05583420012

ser@cere.it +39 011 94 555 11 Linkedin An Group Company

Group Company